Announcing: ComplianceBox

Introducing our new online service: ComplianceBox!

We’ve been hard at work finding a new way to help carriers ensure they are compliant with the National Safety Code while reducing administrative time and costs. As Certified Alberta Transportation Third Party Auditor and New Carrier Compliance Reviewer’s, we know exactly how your records are required to be kept. Now drivers’ can conduct their vehicle inspections (DVIR) using an app on their mobile phone in an easy and compliant way. We’ve done the work to reference the appropriate schedule of the National Safety Code Standard 13 and the Commercial Vehicle Safety Alliance (CVSA) Out of Service Criteria. That means that defects are automatically classified as Major or Minor and it takes the guess work out of your drivers hands. Working in harmony with the mobile apps, our online dashboard gives companies all the tools they need to track the inspections, defects/repairs, lubrications, and scheduled maintenance inspections. We save your staff time by automatically ensuring the reports are completed properly and filed in the right location. Now they can focus on any deficiencies that we have identified.

Driver Daily Vehicle Inspection Reports

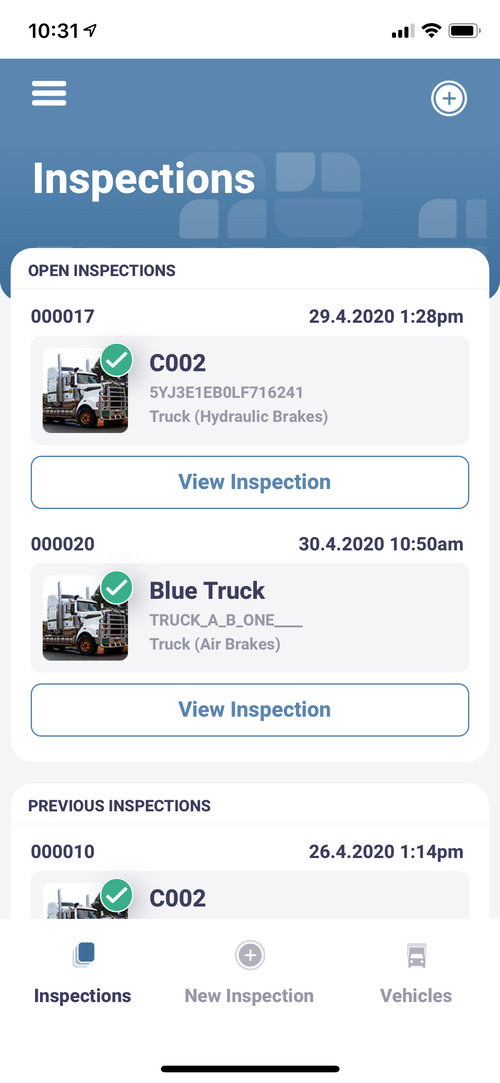

Using their iOS (Apple) or Android smartphone or tablet, a driver has the ability to conduct their required DVIR in a format that is fully compliant with the National Safety Code and applicable provincial regulations.

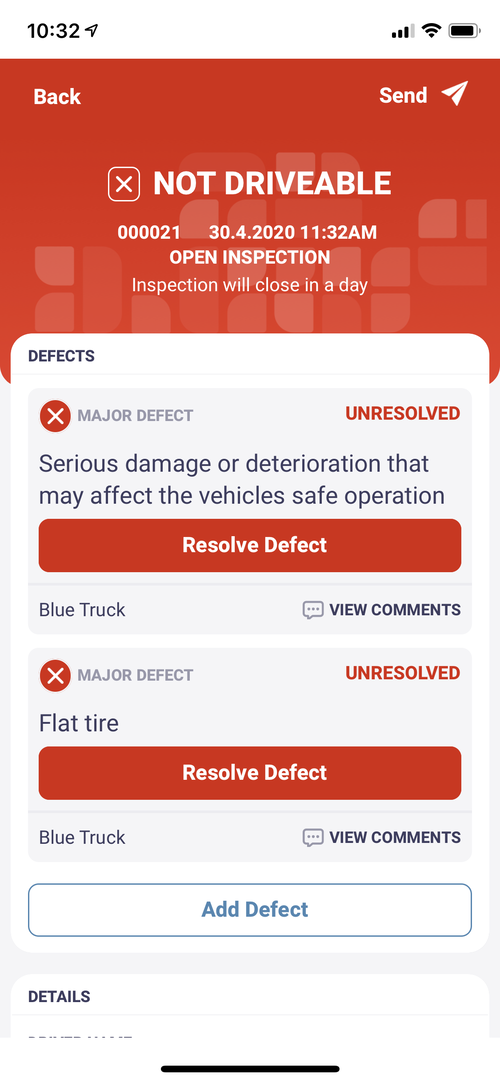

Inspection Overview

Inspections completed in the mobile app are all available for the driver to review later and they automatically close after a 24 hour period (when regulation requires a new inspection to be performed). Drivers can easily see if their inspections are still valid and the current vehicle status.

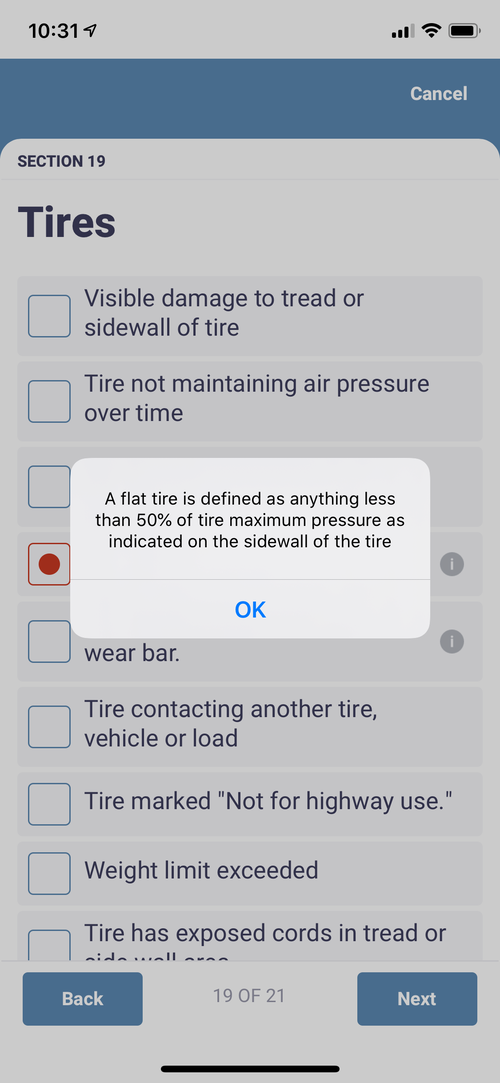

Assisted Classification

Ensuring that defects are properly classified as Major or Minor is very important! While a mobile application cannot replace proper driver training, it can assist drivers to conduct adequate trip inspections. As drivers conduct the inspection in the app all the NSC Standard 13 applicable defects and CVSA Out of Service criteria are listed for review. This provides a reminder to drivers about every component they are required to inspect.

We have also provided additional information on potentially confusing items. For example, flat tires are an item that many drivers struggle with. The inspection standard says that flat tires are a major defect. But, what exactly, is a flat tire? When we are doing training sessions we usually get a wide variety of answers to this question. ‘When the tire is flat?”. “When the tire is off the bead”. “When the tire is low”. Those are all good guesses, however the CVSA Out of Service Criteria gives us the answer: “a tire with less than 50% of the maximum inflation pressure as indicated on the sidewall”.

We then automatically classify the defects drivers have indicated into the appropriate Major/Minor defect categories and determine if the vehicle is “Safe to Operate”.

Defects en Route

Despite popular opinion, a “pre-trip inspection” doesn’t end once the driver puts the vehicle into gear. Drivers are expected to note any defects that arise during their workshift and update their inspection report. ComplianceBox easily captures this information from your drivers.

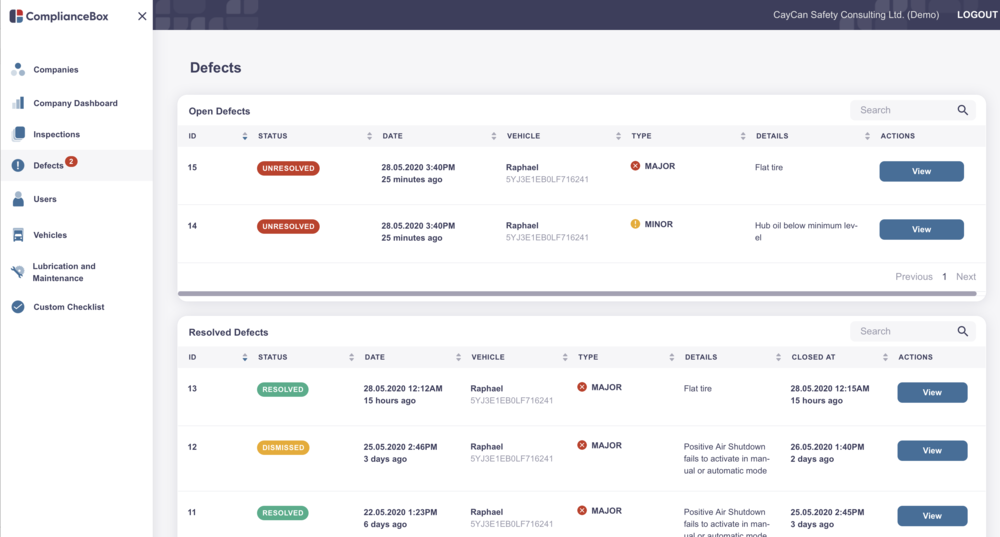

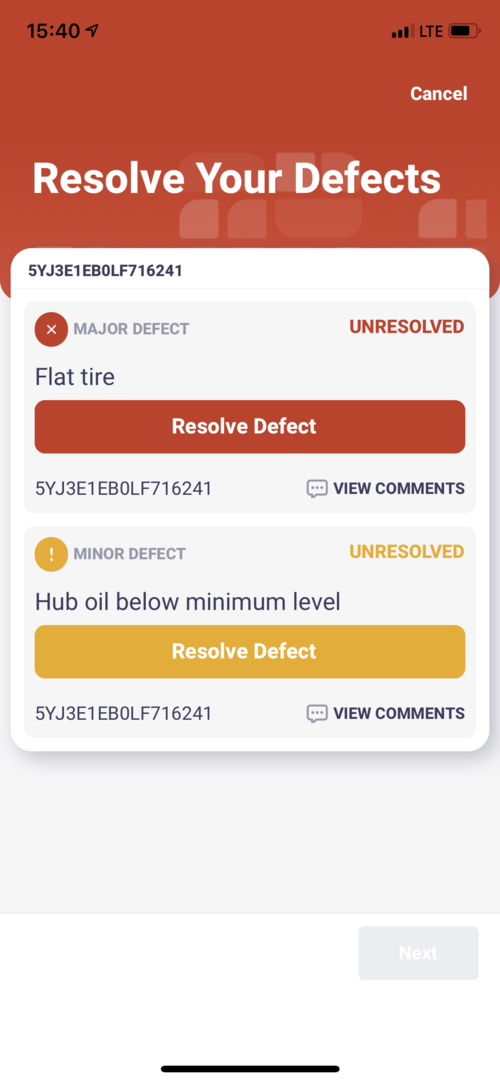

Resolving Defects / Repair Records

Carriers need to ensure that their drivers are properly recording repairs to vehicles when they have found a defect. In an Assessment of Regulatory Compliance Audit or a New Carrier Compliance Review, a carrier may be found in violation if their drivers DVIR’s never show any defects however there are records of repairs or parts used on the vehicle. Instead, it’s a required practice for drivers to record the defect and then the carrier must ensure a properly documented repair is tracked back to the driver’s defect. If the driver performs the repair themselves, ComplianceBox allows them to easily record all the required information and “resolve” the defect. The same can be said if a third party completes the repair. Occasionally third party facilities (like glass repair or mechanic shops) might not record all the required information on their documents to properly qualify as a repair record. Drivers and company staff can record third party repairs with all the required information and even include pictures of the defect or third party documents.

Additionally, drivers are required to review any unresolved defects on vehicles when they perform a new vehicle inspection. Any Major Defects need to be resolved before the inspection can be completed (as the vehicle is not legally permitted to operate with a major defect). Minor defects can be carried forward onto the new inspection report until they are repaired at a later date. This helps carriers in two ways. First, this will alert a new driver of any defects the previous driver may have found on the vehicle. Maybe the last driver found that the hub oil level was low on a trailer. This prompt should trigger the new driver to ensure they are extra attentive to this area when they are doing their inspection. Additionally, this eliminates the problem of defects appearing and disappearing on inspection reports between two drivers. Sometimes during audits we find that Driver A might find a problem, but the defect disappears when Driver B starts using the vehicle. This can be a challenge when we are required to make a determination if the carrier’s drivers are all performing effective trip inspections.

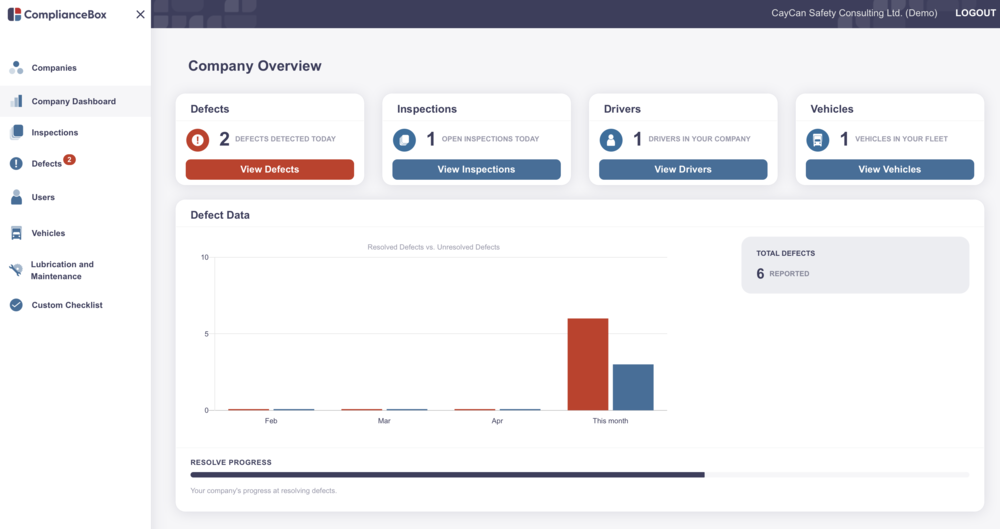

Company Dashboard

Giving your drivers the tools they need to be more compliant is great, but it’s not the complete picture. You need to be aware of your fleet and have access to real time reports. That’s why our dashboard enhances the mobile app by providing you instant notifications, automating record storage, and providing you with effective reporting.

Drivers recorded a defect in one of their inspections? You’ll immediately receive an e-mail alert with all the key information. From the dashboard you can immediately start actioning the repair of the defect. Repairs include a robust note taking system that allows both the driver and the company to post comments and upload pictures. When the defect has been repaired you can mark the defect as resolved right in the dashboard and the vehicle status will be pushed to the driver’s app.

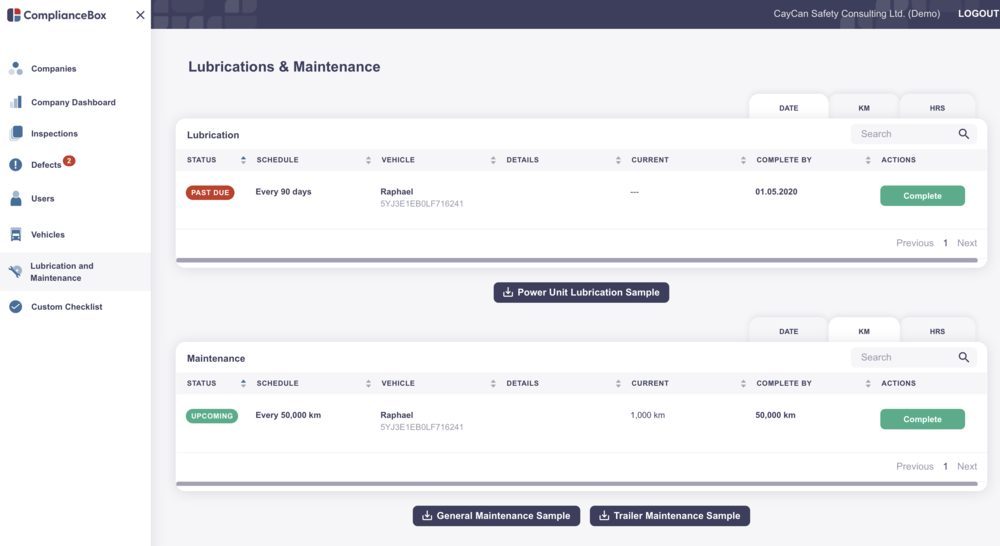

We’ve been focusing on ComplianceBox’s initial features based on items that we see carriers struggle with during the audit process. With that in mind, we built out a robust tracking system to ensure your vehicles are following your written maintenance plan’s lubrication and scheduled maintenance schedule. Now these are easily tracked with all the required information. Administrators can quickly view all of their upcoming required lubrications/inspections so that they can be actioned before they are overdue.

Upcoming Features

We’re working hard to handle all of the items required in a New Carrier Compliance Review or Assessment of Regulatory Compliance Audit. We also want to ensure we have a close relationship with all of our customers. Our partnership means we will prioritize ComplianceBox development to give you the tools you need, when you need them. We have many great ideas for future development in our pipeline.

Made in Alberta Solution and Hosted in Canada

We’re very proud to be an Alberta small business. As such, 100% of the work that has gone into the development of these applications was done in Alberta. We also take the protection of your data very seriously. As such, 100% of the data stored by ComplianceBox is done in servers that are based in Canada. We thank our local customers for support and know that supporting ComplianceBox is supporting Alberta based business. Thank you!

Cost / Subscribing

Everything that we have mentioned so far doesn’t amount to anything if the cost of service is going to be to cost prohibitive. We’re confident that ComplianceBox will save your company time and money (especially for carriers already using a paper based system). That’s why we are introducing a fair pricing model based on the number of drivers or vehicles your company wants to track.

| Number of Vehicles | Monthly Pricing / Vehicle | Monthly Pricing Total | Annual Pricing / Vehicle (Pre-Paid) | Annual Pricing Total (Pre-Paid) |

|---|---|---|---|---|

| 1 | $10.00 | $10.00 | $100.00 | $100.00 |

| 5 | $9.00 | $45.00 | $90.00 | $450.00 |

| 10 | $8.00 | $90.00 | $80.00 | $900.00 |

| 25 | $7.00 | $175.00 | $70.00 | $1,750.00 |

| 50+ | $6.00 | $300.00+ | $60.00 | $3,000.00+ |

Starting July 1, 2025, Manitoba is introducing new marking requirements for regulated vehicles that require a safety fitness certificate to legally operate within the province. This change mandates that these vehicles must display the National Safety Code (NSC) number of the registered owner prominently. This requirement is in addition to the existing mandate for regulated vehicles to be marked with the company logo and/or name….